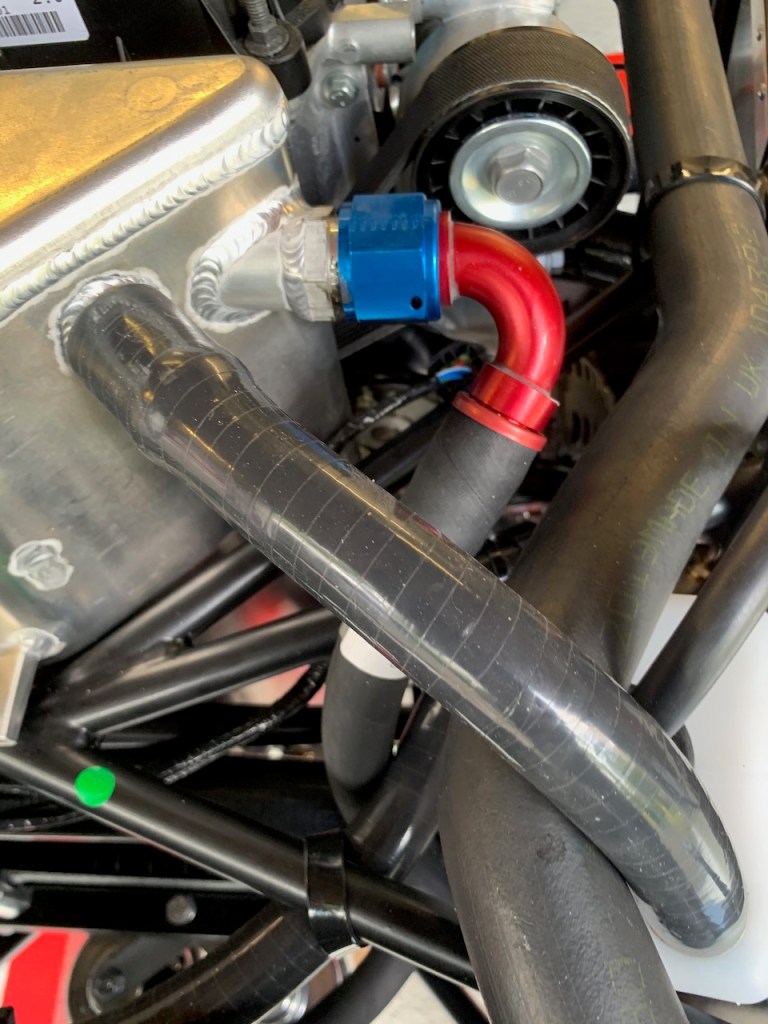

Oil cooler hoses: The oil cooler hoses are difficult to fit, there is not much room in the engine bay and the hoses themselves are quite inflexible. The new manual tells you which is which but finding a route through the maze of pipes whilst keeping clear of the rotating belts and pulleys at the front of the engine is difficult.

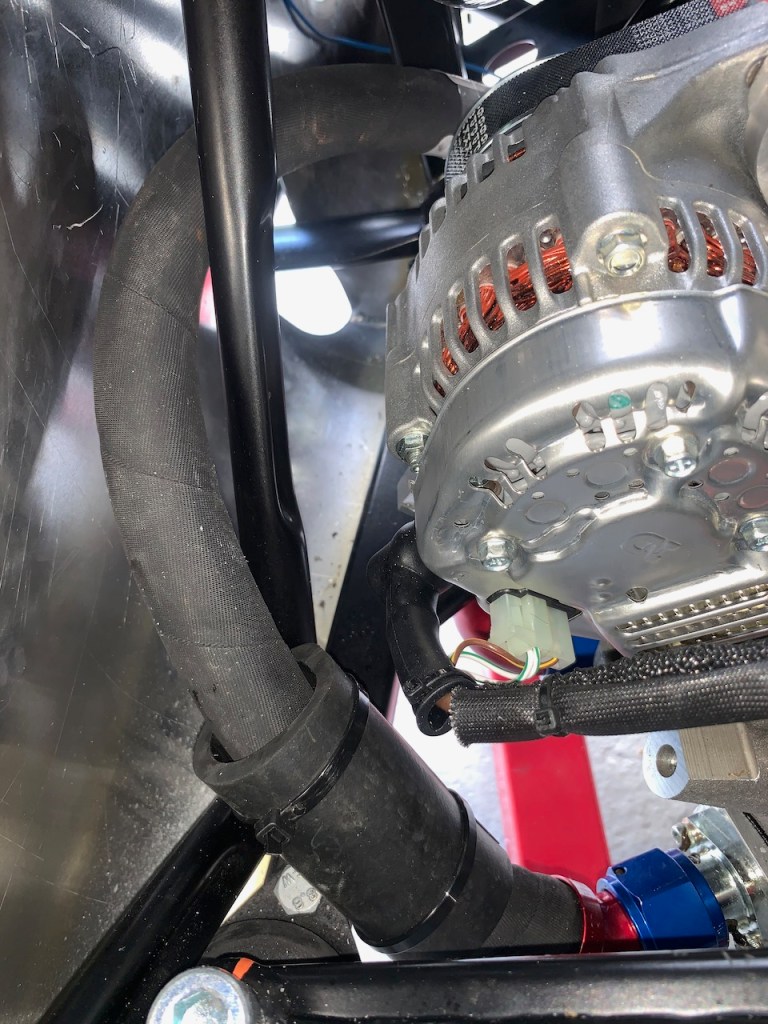

The oil cooler fittings are the ‘Dash-‘ type that use a 37 degree flare on the fitting and the inverse 37 degree flare on the tube to form a metal to metal seal. The fittings are aluminium so great care must be taken not to cross thread. The best way to fit them is to use plenty of copper slip on the threads and carefully hand tighten until resistance is felt and then use a large spanner to nip them up with a final 1/8 turn.

Although everything is connected and I’ve avoided moving parts I am still not sure I have the optimal routing between the chassis members (email sent to Caterham for some advice).

- The pipe exiting the front of the oil cooler plate is clear of the chassis but runs close to the 90 degree corner of the rear wishbone bracket – I think I will take a file to radius this corner and then glue some IVA trim to the edge for piece of mind.

- The pipe exiting the rear of the oil cooler plate goes up inside the engine bay between a diagonal chassis member and the side skin. Whilst this is clear of the alternator pulley / belt it does run close to the chassis. To avoid the risk of chaffing I’ve used a piece of split / cable tied radiator hose as a conduit over the bottom chassis rail and will use some thinner tubing (or possibly a section of bicycle tyre and cable ties) to protect the hose where it rests against the diagonal chassis member.

Oil cooler sump plate connections

Oil tank top hose

Radiator tube conduit

Bracket corner to radius & edge trim