The collector and catalyst are one unit and are a push fit over the ends of the four primaries. I found it helped to loosen the primary bolts slightly to give a little play in the tubes and help line everything up to the collector.

The collector is held on by two compression spring and hook assemblies that act as a tension fitting to pull the two parts of the exhaust system together.

Two bent pieces of wire with hooks on the end pass in opposite directions through the compression spring and the wire loops at each end need to be slid over the hooks on the primary and collector.

The spring must be compressed to give enough reach to get over the ends of the exhaust hooks. The recommended ‘cable-tie method’ is well documented on other blogs and involves compressing the spring in a vice and using 3 or 4 cable ties to hold it fully compressed whilst the whole lot is slid over the exhaust hooks. Once in place the cable ties are cut and the tension pulls the primary and collector together. The last job at this point was to torque up the primary gasket / exhaust manifold bolts to 34Nm.

Note that I installed the lambda sensor into the collector before fitting to the primaries to avoid any risk of slipping with a spanner and damaging the bodywork.

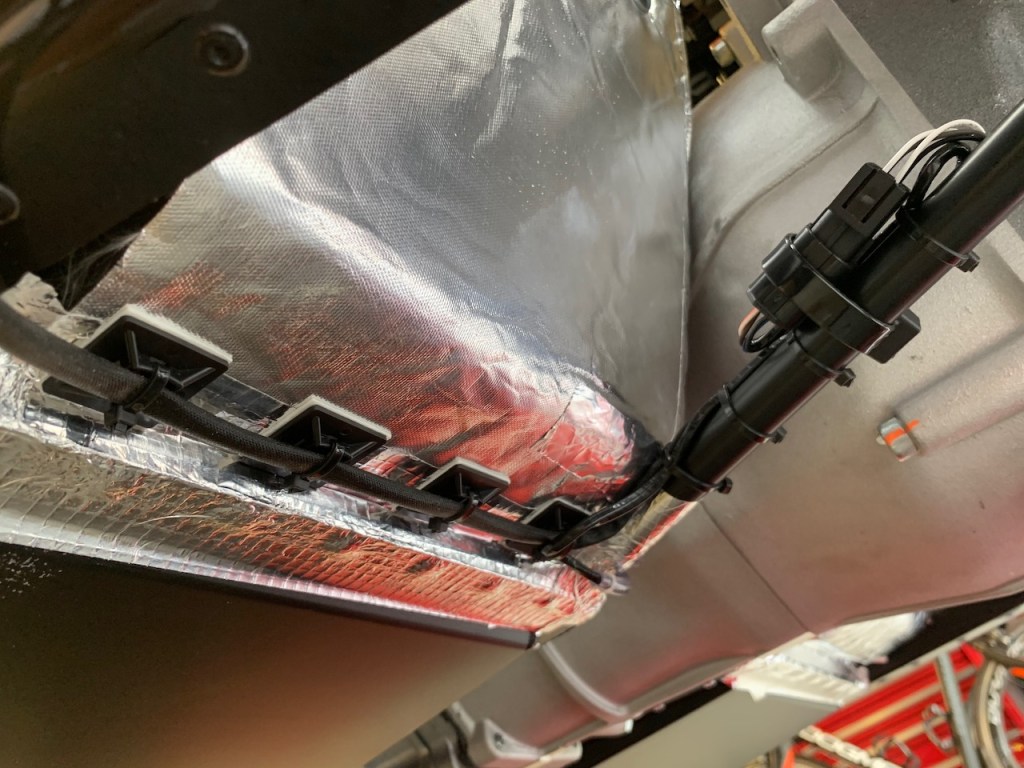

The lambda sensor needs to be connected to the wiring loom and the wiring secured to the chassis. I stuck cable tie blocks with 3M self adhesive pads to the heat shield along the chassis rail and then tidied everything up with more cable ties before covering it all with aluminium tape. I even used a small section of washer pipe to protect the loom cable as it passed around the bottom edge of the footwell. There is a lot of surplus cable to get rid of so I doubled this back on itself and secured it with the Econoseal connector to the chassis rail with cable ties.

The last job was to fit the black heat shield which is secured to the catalyst with two very large jubilee clips.